Quick couplings (also known as quick connect or quick disconnect couplers) are essential for hydraulic and pneumatic systems, allowing for fast and easy connection and disconnection of fluid lines. But when it comes time to replace a worn or damaged coupling, it can be tricky to figure out exactly what type, size, and thread you need—especially with so many styles and standards on the market.

In this guide, we’ll walk you through how to identify your current quick coupling to ensure you get the correct replacement. Whether you’re working with construction, agricultural, or industrial equipment, this step-by-step guide will help you match it right the first time.

1. Identify the Coupling Type (ISO Standard or Series)

Quick couplings come in different standard types, each with specific dimensions and design features. The most common types include:

ISO 7241 Series A (ISO A)

- Common in agricultural and construction equipment

- Ball-locking mechanism

- Interchangeable with brands like Parker 6600, Faster ANV, and Hansen HA

ISO 7241 Series B (ISO B)

- Widely used in industrial applications

- Poppet valve with ball locking

- Compatible with Parker 60 Series, Faster HNV, and Snap-Tite 72 Series

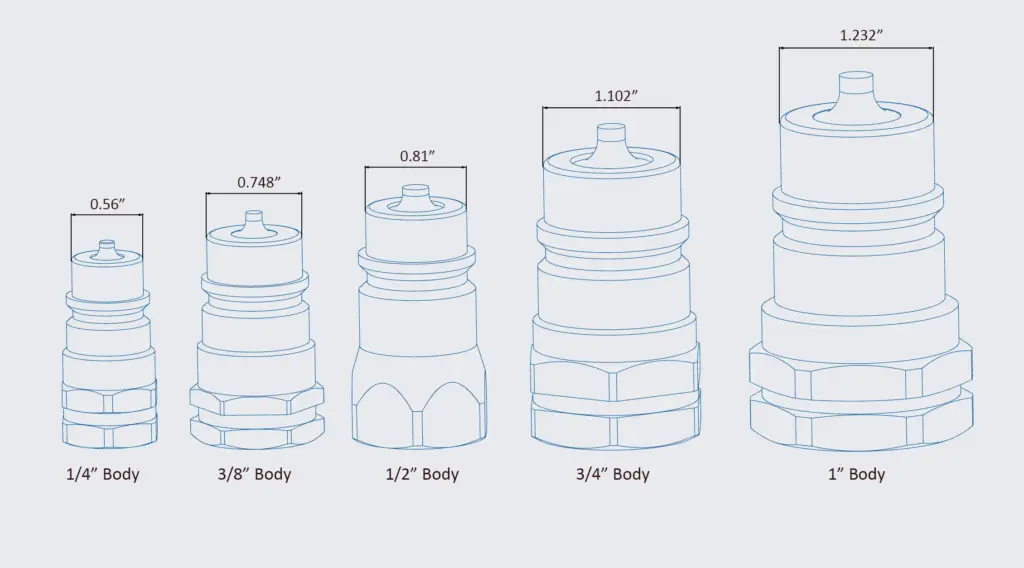

ISO 5675 (Agricultural Standard)

- Typical in tractors and implements (e.g., John Deere, Case IH)

- Often used with poppet valves and ball-lock sleeves, Old also used with Ball Valves

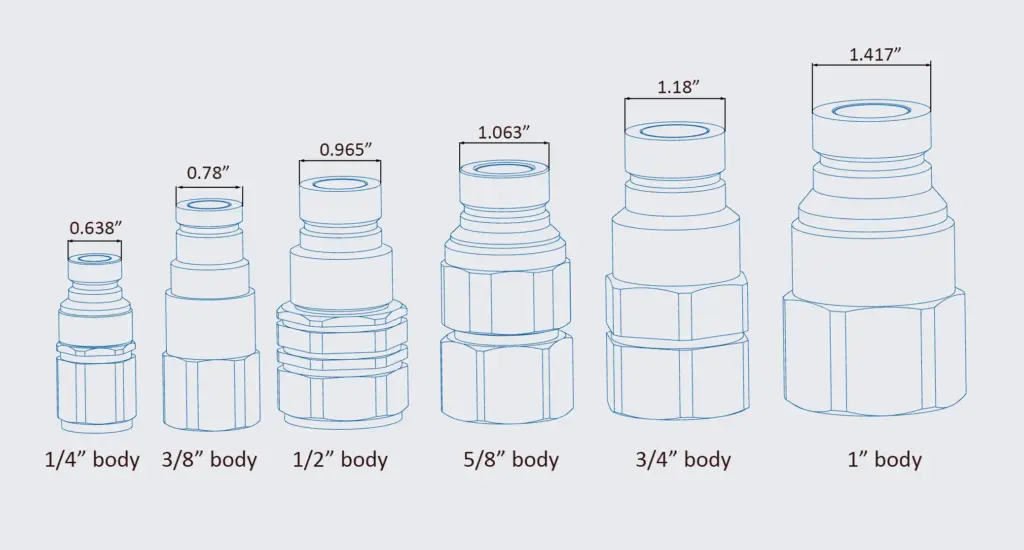

Flat Face Couplings (ISO 16028)

- Used in high-pressure hydraulic systems and skid steer loaders

- No fluid loss during disconnection ( No-Spill)

- Cleaner and safer, ideal for construction and forestry

Push-to-Connect / Push-Pull Types

- Easy connection with one hand

- Common in tractor loaders and front-end attachments

Other Quick Couplings

There are other standards, such as ISO 14540, ISO 14541, and some popular interchangeable quick connectors in the industry as corporate standards, such as wet-line quick connectors, etc.

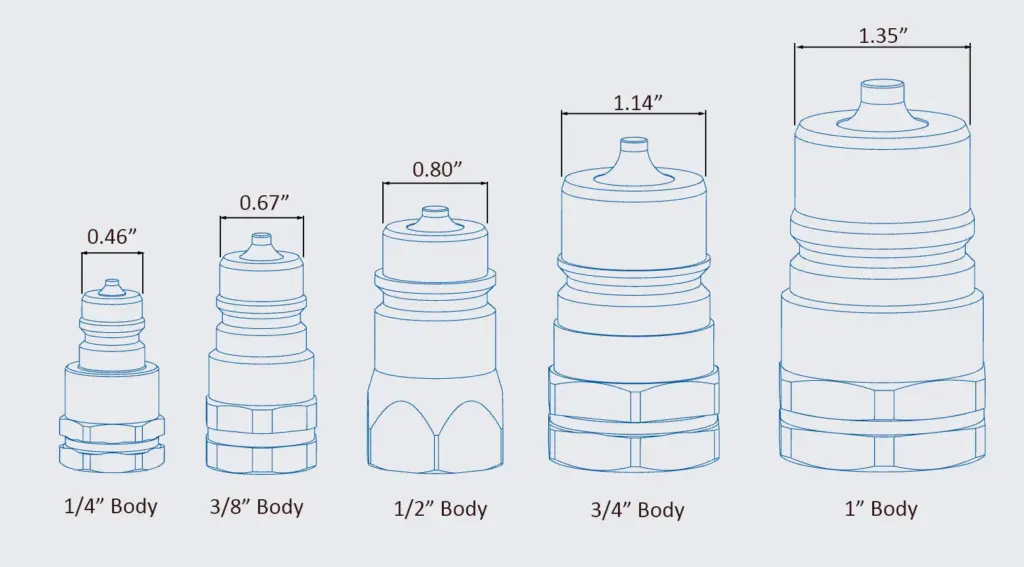

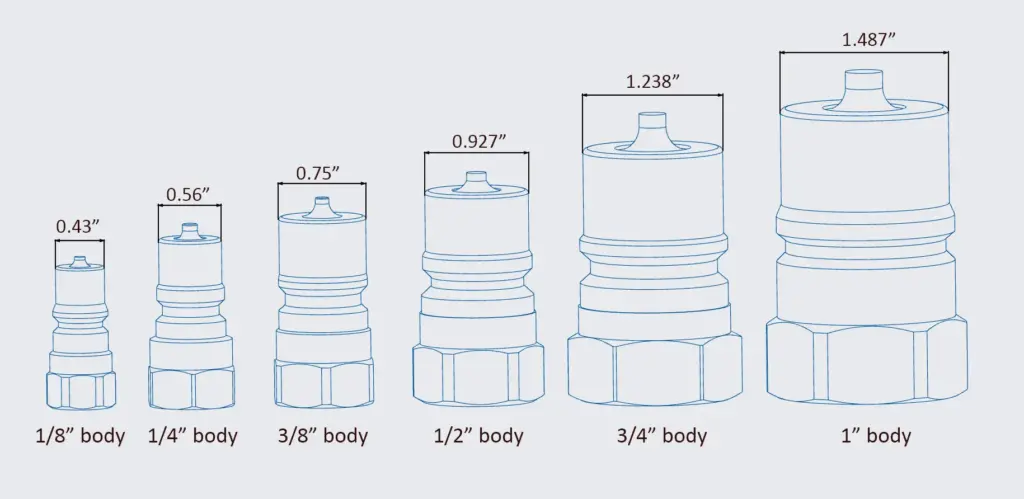

2. Determine the Coupling Size

Coupling “size” refers to the nominal size of the internal flow passage, NOT the overall dimensions.

Common Sizes:

- 1/4″

- 3/8″

- 1/2″

- 5/8″(The Flat Face Coupler has this body size)

- 3/4″

- 1″

- 1-1/4″

- 1-1/2″

- 2″

How to Measure:

- Measure the Dimensions of the male tip ( usually the diameter)

- Compare with a size chart for the ISO series in question ( we list some in images)

Caution: Nominal size does not always match the thread size! For example, a 1/2″ coupling might have a G 3/4 thread.

| Size | ISO A | ISO B | ISO 5675 | ISO 12068 |

|---|---|---|---|---|

| 1/8″ | – | 0.43″ | – | – |

| 1/4″ | 0.46″ | 0.56″ | 0.56“ | 0.64“ |

| 3/8″ | 0.67″ | 0.75″ | 0.75“ | 0.78” |

| 1/2″ | 0.80″ | 0.92″ | 0.80“ | 0.96“ |

| 5/8″ | – | – | – | 1.06” |

| 3/4″ | 1.14″ | 1.24″ | 1.10“ | 1.17“ |

| 1″ | 1.35″ | 1.48″ | 1.23“ | 1..41” |

| 1-1/4″ | 1.77″ | – | – | 1.73“ |

| 1-1/2″ | 2.16″ | 1.75″ | – | 2.24“ |

| 2″ | 2.56″ | 2.49“ | – | 2.87” |

3. Identify the Thread Type

Threads are critical when replacing or adapting couplings. The most common thread types include:

NPT (National Pipe Thread – Tapered)

- Tapered thread (widens as it goes deeper)

- Common in North America

- Marked in inches: 1/4″, 3/8″, 1/2″, etc.

- Requires sealant (e.g., PTFE tape)

BSPP (British Standard Pipe Parallel) – Also called G Thread

- Straight thread

- Often used in Europe and Asia

- Needs a bonded washer or O-ring for sealing

Metric Threads

- Usually specified by outer diameter and pitch (e.g., M22x1.5)

- Common in equipment made in Europe and Asia

How to Check Your Thread Type:

- Use a thread pitch gauge and calipers to measure:

- Outer diameter (OD) of the thread

- Thread pitch (distance between threads)

- Compare with an NPT vs BSPP vs Metric chart

- Alternatively, bring your fitting to a hydraulic shop for thread identification

Extra Tips for Easy Replacement

- Buy as a set (male + female) to ensure compatibility

- Check pressure ratings to match your system’s requirements

- If you’re replacing a tractor quick coupling, consider brands like John Deere or Case IH – OEM specs can vary slightly

- Look for dust caps if your system works in dirty environments – they prolong coupling life

Final Thoughts

Identifying the correct quick coupling replacement doesn’t have to be complicated. By checking the type, size, and thread, you’ll save time, avoid leaks, and ensure your hydraulic system runs smoothly.

Still unsure? Contact our team or send us photos and measurements of your couplings — we’re happy to help you find the perfect match!